Inside the Studio: The Art and Precision of Modern Custom Fabrication

Modern custom fabrication blends skill, design, and technology to produce pieces that are both functional and artistic. At the heart of this craft is a deep understanding of materials, tools, and techniques that shape the very objects we use and admire every day. Whether it’s intricate furniture designs, architectural elements, or unique art installations, custom fabrication allows for the creation of personalized pieces that reflect individual tastes and meet specific needs.

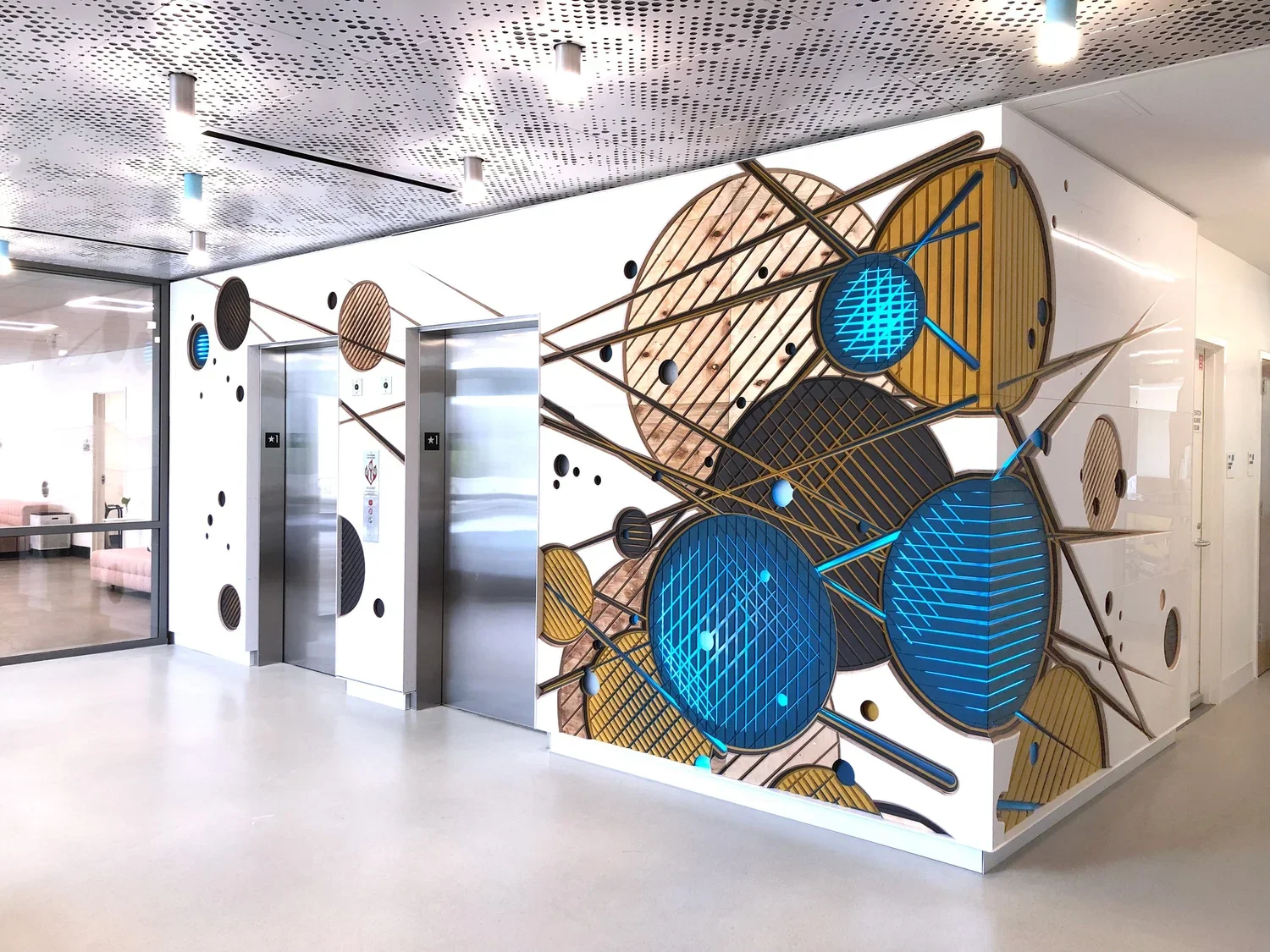

At Tecture Fabrication Studio, this approach is not just a profession; it's an art form. Here, every project begins with the intent to create something distinctive—something that marries precision and creativity in a way that mass production can’t. In this article, we’ll take you inside a fabrication studio to understand what makes modern custom fabrication an essential part of contemporary design and how it’s shaping the future of art and functionality.

What Is Modern Custom Fabrication?

Modern custom fabrication is a precise process that involves designing, crafting, and assembling components to create a tailored piece of work. It combines engineering, craftsmanship, and design, ensuring that each piece is unique. At Tecture Fabrication Studio, this process is applied to everything from furniture to sculptures, and from architectural features to intricate patterns used in modern interiors. Custom fabrication allows for a level of detail and personal input that off-the-shelf products simply can’t offer.

This process usually involves working with a variety of materials, such as metals, wood, glass, plastics, and composites, depending on the project's requirements. The skill of the fabricator, the quality of the materials, and the tools used are all essential to the final product’s precision and longevity.

The Art of Fabrication: Precision Meets Creativity

Fabrication is both a science and an art. The science lies in the accuracy required to shape materials into the desired form. The art comes from the ability to blend these materials in aesthetically pleasing ways while still maintaining structural integrity.

Crafting Modern Fabric Patterns

In the realm of modern custom fabrication, one of the key elements is the creation of fabric patterns that define the aesthetic of a space or object. Modern fabric patterns are no longer limited to simple prints or textures. Today, they incorporate geometric shapes, abstract designs, and custom illustrations that bring a contemporary flair to any design.

At Tecture Fabrication Studio, fabric patterns are crafted using a variety of techniques, including laser cutting, 3D printing, and CNC machining. These methods allow for greater flexibility in the design process, enabling artists and fabricators to create intricate, detailed patterns that would be impossible to achieve with traditional methods.

For example, a custom-designed fabric pattern for a piece of furniture might involve a carefully planned combination of wood grain and metallic finishes, each layer serving a specific purpose to enhance the overall visual appeal. This approach not only elevates the design but also ensures that the finished product complements its environment.

The Role of Technology in Modern Fabrication

While the craftsmanship of the fabricator is critical, technology plays a huge role in the precision and speed of modern custom fabrication. Digital tools such as CAD (Computer-Aided Design) software allow designers to create intricate blueprints that are translated into real-world objects using automated machines. CNC machines, laser cutters, and 3D printers can all take instructions from digital files, ensuring that each cut, curve, and pattern is executed with exacting detail.

This integration of technology allows for better reproducibility and consistency in custom fabrication, while also expanding the possibilities of what can be created. For example, 3D printing makes it possible to create highly detailed structures, whether they’re functional components or purely artistic pieces. Meanwhile, laser cutting offers precision in cutting fabric patterns or other materials, ensuring that the final product is flawless.

Why Choose Custom Fabrication?

The allure of custom fabrication lies in the ability to create something tailored exactly to your specifications. In contrast to mass-produced items, custom pieces offer a level of personalization that can elevate the quality and uniqueness of a project.

Unique Design and Personalization

One of the primary advantages of modern custom fabrication is that each piece is entirely unique. Custom fabrication allows for the creation of objects that reflect the personal tastes, needs, and preferences of the client. Whether you're designing a statement piece of furniture, a custom art installation, or an architectural feature, custom fabrication ensures that the final product aligns perfectly with your vision.

For example, at Tecture Fabrication Studio, clients often collaborate with designers and fabricators to create art pieces that are tailored to the specific theme or atmosphere of their space. This personalized approach allows for a stronger emotional connection to the final product, making it not just an object, but an integral part of the environment.

High Quality and Durability

Mass-produced products often compromise on quality to meet price points, but custom fabrication prioritizes durability and craftsmanship. By using high-quality materials and skilled techniques, custom fabrication ensures that each piece is built to last.

For instance, when creating custom furniture, the fabricator can select premium woods, metals, and finishes that not only look beautiful but also stand up to everyday wear and tear. Similarly, custom art fabrication can result in pieces that are both visually stunning and able to withstand the test of time.

Flexibility in Design

Unlike mass-produced items, custom fabrication offers virtually unlimited flexibility in design. Clients can specify every detail, from the material choice to the texture, color, and scale of the piece. Whether you're looking for a bold geometric pattern, a traditional motif, or something entirely unique, custom fabrication allows you to create something that is truly one-of-a-kind.

At Tecture Fabrication Studio, this flexibility is seen in the range of projects undertaken. From small, intricate pieces of jewelry to large-scale public art installations, the studio can adapt to any creative challenge, using modern techniques to bring complex ideas to life.

The Process of Custom Fabrication

Creating a custom piece involves several stages, each requiring skill and attention to detail. At Tecture Fabrication Studio, the process is a collaborative effort between designers, fabricators, and clients, ensuring that the final product meets all aesthetic and functional requirements.

Step 1: Conceptualization and Design

The first step in the fabrication process is conceptualizing the design. This is where the vision begins to take shape. Whether it’s for a piece of furniture, a decorative element, or a large-scale installation, the design phase is crucial. Here, the client’s ideas are combined with the expertise of the designers to create detailed plans and digital renderings.

This stage also involves choosing materials, determining dimensions, and finalizing the overall aesthetic of the piece. For modern fabric patterns, this might include selecting colors, textures, and geometric shapes that will work best for the project’s intended purpose.

Step 2: Material Selection

Once the design is complete, the next step is selecting the materials. Modern custom fabrication relies on a wide range of materials, each chosen for its specific properties. Whether it’s a strong metal for structural support, a lightweight plastic for intricate patterns, or a durable wood for fine detailing, material selection plays a key role in the success of the project.

At Tecture Fabrication Studio, careful attention is paid to the sourcing of high-quality materials, ensuring that each piece is both functional and aesthetically pleasing.

Step 3: Fabrication and Assembly

With materials and design in place, the fabrication process can begin. This involves the actual crafting of the piece, whether that’s cutting, shaping, welding, or assembling various components. At this stage, modern machines like CNC routers and laser cutters may be used to ensure precision, while skilled artisans manually handle the more intricate tasks.

For custom art fabrication, this step often involves the creation of sculptures or other artistic pieces, where the artist’s vision comes to life through the materials and techniques chosen earlier in the process.

Step 4: Finishing and Detailing

The finishing process is where the final touches are added. This includes sanding, painting, polishing, or staining, depending on the material. The attention to detail in this stage ensures that the final piece not only looks beautiful but is also functional and durable.

In the case of modern fabric patterns, this step may involve applying textures or finishes to the fabric to enhance its visual impact. The precision of the finishing work is critical in achieving the desired effect and ensuring that the piece is ready for use or display.

Modern Fabrication

The world of custom fabrication has found a natural home in the art world. Artists are now using modern fabrication techniques to create sculptures, installations, and other pieces that push the boundaries of what’s possible.

Custom art fabrication allows artists to experiment with new forms and materials that were previously out of reach. For example, metal, glass, and wood can now be combined in intricate ways that produce stunning, durable works of art. This has led to a rise in the popularity of public art installations, where custom fabrication techniques are used to create large-scale, site-specific works.

Conclusion

Modern custom fabrication is more than just a technical process—it is a blend of art, engineering, and craftsmanship that results in the creation of truly unique and functional pieces. Whether it's creating intricate modern fabric patterns or designing a custom art fabrication project, the possibilities are limitless. Tecture Fabrication Studio continues to push the boundaries of what can be achieved with modern fabrication, offering clients personalized, high-quality designs that stand the test of time.

By combining the best of craftsmanship with the precision of modern tools, custom fabrication ensures that every piece is not only a work of art but a reflection of the individual or organization it represents.

FAQs

1. What is modern custom fabrication, and how does it differ from mass production?

Modern custom fabrication refers to the process of designing and creating unique, tailored pieces or products by hand or with the aid of advanced technology, such as CNC machines, 3D printing, or laser cutting. This approach focuses on quality, precision, and personal input, allowing for a high degree of customization. Unlike mass production, which typically involves standardized designs made in bulk, custom fabrication offers personalized solutions tailored to individual specifications, resulting in one-of-a-kind creations.

At Tecture Fabrication Studio, we focus on crafting pieces that reflect your specific needs and preferences—whether it's a custom furniture design, modern fabric patterns, or art installations. The primary distinction lies in the attention to detail, craftsmanship, and the ability to create something unique that aligns perfectly with a client’s vision.

2. How long does a custom fabrication project typically take?

The timeline for a custom fabrication project varies depending on the complexity, size, and materials involved. For smaller pieces like custom furniture or decorative elements, the process may take a few weeks to a month. For larger-scale projects such as architectural features or custom art installations, the process could take several months from design to completion.

At Tecture Fabrication Studio, we collaborate closely with clients during each phase—from initial conceptualization to final production—to ensure that timelines are met without compromising on quality. Each step involves careful planning and precision work, from selecting the right materials to fine-tuning details in the fabrication process, ensuring the final product exceeds expectations.

3. Can I incorporate my own designs or ideas into the fabrication process?

Absolutely! One of the core benefits of modern custom fabrication is that it allows you to incorporate your own ideas and designs. Whether you have a rough sketch or a fully developed blueprint, the team at Tecture Fabrication Studio will work with you to bring your vision to life.

We utilize digital tools like CAD (Computer-Aided Design) software to create precise and detailed models, which are then translated into the fabrication process using cutting-edge machinery. If you’re looking to incorporate modern fabric patterns or specific elements of custom art fabrication, we ensure that every detail is carefully executed to match your vision.

This level of personalization ensures that the final product aligns perfectly with your aesthetic, functional, and structural requirements.

4. What materials are typically used in custom fabrication projects?

The materials used in modern custom fabrication depend on the intended purpose of the project, but some of the most common materials include:

Wood: Ideal for furniture, architectural elements, and sculptures. Its natural beauty and versatility make it a popular choice for custom designs.

Metal: Often used for structural components, furniture, and modern art pieces. Materials like stainless steel, aluminum, and copper are popular choices for their strength and durability.

Glass: Perfect for creating sleek, modern designs or decorative pieces. Glass can be used in combination with other materials, such as metal or wood, to create stunning, lightweight structures.

Plastics & Composites: These materials are often used for custom patterns or parts that require flexibility and precise detailing, such as 3D-printed components.

Textiles and Fabrics: When creating custom patterns for furniture or other items, fabrics and textiles can be selected based on texture, color, and pattern to complement the overall design.

At Tecture Fabrication Studio, we carefully select materials based on the specific requirements of each project, ensuring that the final piece is not only visually striking but also durable and functional.

5. How can custom fabrication benefit businesses or commercial projects?

For businesses, modern custom fabrication offers the advantage of creating unique, branded environments or functional products that stand out. Whether it’s for a retail space, office interior, or art installation, custom fabrication allows for the creation of elements that enhance the brand’s identity and customer experience.

Custom pieces can also serve as a long-term investment. They tend to be more durable than mass-produced items and can be tailored to fit the specific needs of the business, reducing the need for constant replacements or upgrades.

For example, Tecture Fabrication Studio has worked with businesses to create custom signage, architectural elements, and bespoke furniture that aligns with their branding. The use of modern fabric patterns and materials allows businesses to create an atmosphere that is both functional and visually compelling.